Metal nanoparticles have emerged as a new platform for developing highly efficient catalysts and received wide consideration, which has many advantages such as high dispersion and catalytic efficiency. The activity and stability are key factors that influence the practical application of catalysts in industry, and thus to efficiently and facilely tune particle size and stability of catalysts are major concerns and keep as a challenge for the researchers.

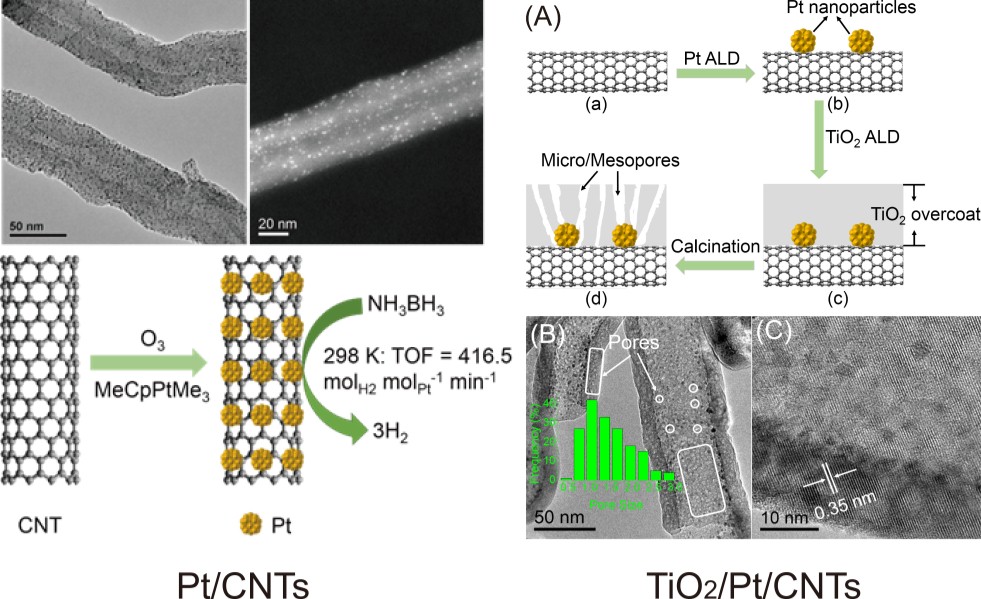

Recently, we applied a general atomic layer deposition (ALD) method to synthesize uniformly dispersed Pt nanoparticles with controlled size supported on multi-walled carbon nanotubes (CNTs) with (methylcyclopentadienyl)trimethylplatinum (MeCpPtMe3) as Pt precursor and ozone as reactant gas. All the ALD-prepared Ptx/CNTs (x represent Pt ALD cycle number, i.e., 10, 20 and 40) catalysts with various cycle numbers show excellent catalytic activities towards hydrolysis reaction of ammonia borane (AB), and especially the Pt/CNTs catalysts produced with 20 ALD cycles (1.8 nm) exhibit the highest hydrogen generation rate among the ALD-prepared catalysts, with a total turnover frequency value as high as 416.5 molH2·molPt-1·min-1. To improve the durability of Pt/CNTs catalysts, porous TiO2 overcoats with controlled thickness (13.4 nm, 300-cycle TiO2) were further deposited on the catalysts as a protective layer to prevent the mobility/leaching of Pt nanoparticles on CNT supports. Our results indicate that the porous TiO2 overcoat can improve the durability of Pt/CNTs catalysts while preserving their catalytic activities. This can be ascribed to the formation of micro/mesopores due to the densification of an amorphous TiO2 coating to a crystallized TiO2 during the calcination process, and it seems that the pores in TiO2 overcoats are large enough and such thickness of TiO2 overcoats does not influence the access of AB molecular to the coated Pt nanoparticles as well as the diffusion of targeted products (H2) because no activity decrease is observed in our experiments.

In summary, the uniformly dispersed Pt nanoparticles deposited on CNTs with narrow size distribution and uniform TiO2 overcoats on Pt/CNTs were successfully synthesized by ALD, fully demonstrating the advantages of ALD in synthesizing nanocatalysts with high activity and stability. The corresponding results have been published in Catalysis Science & Technology and highlighted as cover paper.

负载型金属纳米催化剂具有广泛的应用前景,其具有分散度高、催化活性好等优点。催化剂的活性及稳定性是影响其实际应用的主要因素,因而如何有效调控催化剂颗粒的粒径及稳定性是研究者普遍关注的问题及面临的挑战。

最近,我们组利用原子层沉积技术(ALD)在多壁碳纳米管(CNT)上沉积Pt纳米颗粒,得到高分散、高活性的Pt/CNTs催化剂,用于催化氨硼烷(AB)水解制氢。通过调节循环次数制备了10、20、及40循环的Pt/CNTs纳米金属催化剂,Pt颗粒的平均粒径分别为1.2 nm,1.8 nm及2.0 nm,实现了对金属Pt纳米颗粒的精确调控。研究发现,所制备的Pt/CNTs催化剂对AB水解制氢反应显示优异的催化性能,其TOF值最高达416.5 molH2·molPt-1·min-1 (1.8 nm),高于大多数文献报道的数据。为了进一步提高催化剂的稳定性,我们在Pt/CNTs催化剂的表面沉积一层厚度约为13.4 nm的TiO2薄膜,经过焙烧后即得到多孔TiO2包覆的TiO2/Pt/CNTs催化剂。实验结果表明,TiO2包覆层不仅没有降低催化剂的活性,反而使得催化剂的稳定性得到明显的改善,这是由于平均孔径为2 nm的孔并不影响反应物(NH3BH3)及产物(H2)分子的扩散。通过XRD、TEM等表征发现金属Pt在CNTs上高度均匀分散及TiO2均匀包覆在催化剂表面,充分体现了ALD技术在制备纳米催化剂方面的优势。相关结果已发表在Catalysis Science & Technology,并被选为封面文章重点报道。

原文链接:http://sci-hub.tw/10.1039/C6CY01960A

?

903 Group, Institute of Coal Chemistry, Chinese Academy of Sciences, All Rights Reserved

联系电话:0351-4040081 邮箱:qinyong@sxicc.ac.cn 地址:山西省太原市桃园南路27号

Address: 27 South Taoyuan Road, Taiyuan, Shanxi, P.R.China Tel: 0351-4040081 Email: qinyong@sxicc.ac.cn

当前位置:

当前位置: